Submersible Mixer

Product Details:

- Power Consumption 0.75 Kilowatt (kW)

- Feature Homogenized Mixing, Durable, High Quality, Good for Equalization

- Automatic Grade Full Automatic

- Voltage 75 Watt (w)

- Product Type Submersible Mixer

- Water Source River Water

- Material Stainless Steel 316

- Click to view more

Submersible Mixer Price And Quantity

- 1 Nos

- 400000.0 INR/Unit

Submersible Mixer Product Specifications

- Submersible Mixer

- 0.75 Kilowatt (kW)

- Full Automatic

- 75 Watt (w)

- Homogenized Mixing, Durable, High Quality, Good for Equalization

- AC/DC

- River Water

- Stainless Steel 316

Submersible Mixer Trade Information

- Mundra

- Cash Advance (CA) Cheque

- 10 Nos Per Month

- 40 Days

- Yes

- Contact us for information regarding our sample policy

- Wooden Pallet Packing/ also available as per client's requirement

- Middle East Africa Asia Australia Central America North America South America Eastern Europe Western Europe

- Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Meghalaya Chandigarh Goa Jharkhand Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Tamil Nadu Daman and Diu Odisha Punjab Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal All India South India Mizoram Manipur Andhra Pradesh Bihar Sikkim Telangana

- ISO 9001:2015 TUV Nord certified and MSME certified

Product Description

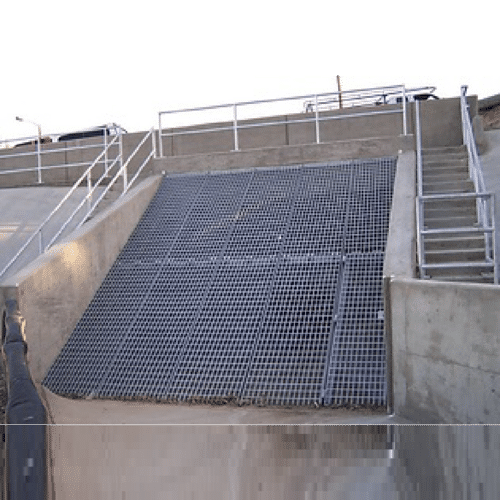

A submersible mixer is a type of mixing equipment used in various industries for blending, agitation, and homogenization of liquids or slurry. Unlike conventional mixers that operate from the top of the tank or vessel, submersible mixers are submerged directly into the substance being mixed. This design allows for efficient mixing without the need for complex mechanical structures above the liquid surface.

Here are some key features and components of a typical submersible mixer:

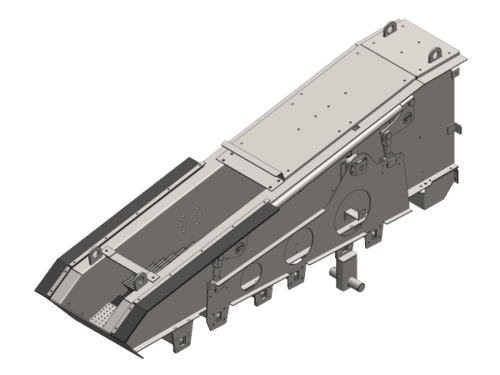

1. Motor: Submersible mixers are equipped with an electric motor capable of operating underwater. The motor is usually sealed to prevent water from entering and damaging its internal components.

2. Impeller: The impeller is the rotating component responsible for creating fluid motion and mixing. It may come in various designs depending on the application requirements, such as propeller-type, axial-flow, or radial-flow impellers.

3. Shaft: The shaft connects the motor to the impeller and transmits the rotational motion generated by the motor to the impeller.

4. Seals: Seals are essential to prevent leakage of the liquid into the motor and electrical components. They ensure the submersible mixer operates safely and efficiently in submerged conditions.

5. Housing: The housing encases the motor and provides structural support for the mixer. It is typically made of corrosion-resistant materials such as stainless steel or reinforced plastics.

6. Mounting: Submersible mixers can be mounted in various ways depending on the application. They may be suspended from above using chains or brackets, or they may be installed on the tank bottom using specialized mounting systems.

Submersible mixers find applications in wastewater treatment plants, chemical processing, food and beverage production, and other industries where mixing of liquids or slurry is required. They offer advantages such as efficient mixing, compact design, and the ability to operate in challenging environments. Additionally, they can be easily installed and maintained compared to some other types of mixers.

Disclaimer: Prices are subject to change based on individual client requirements. The final cost of services/products may vary depending on the specific needs and preferences of each client. Please contact us for a personalized quote tailored to your unique specifications.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese